Workflow in the Shop - What it Takes to Make CNC Lathe Parts

The workflow varies from shop to shop, but we will breakdown what it might take to process a CNC lathe part.

Order received in the shop

Review of the part and print / team meeting

A work order / job routing is created

Material is ordered

Part is programmed in CAM software

The CNC Program is run through verification software

Special tooling is ordered

Material arrives in the shop

The CNC machine is setup

The program is ran with no material in the CNC lathe, this is called a dry run

If the program runs okay, the material is loaded in the CNC lathe

The rapid movements are turned down on the lathe, and the program is proved out with a skilled machinist

The machinist makes a part to print dimensions

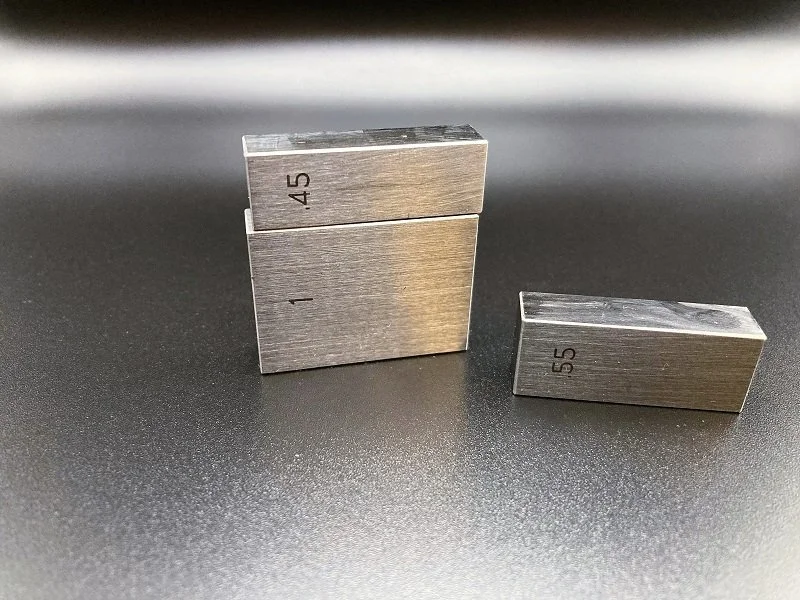

The quality control department inspects the part

The machinist is given the okay, to make more parts in production

The machinist inspects parts based off the AQL (Acceptance Quality Limit) guidelines

The parts are finish machined

The parts are inspected by quality control

The parts are packaged

The parts are shipped

The work order is closed