The Basics of Gage Blocks

Gage blocks (also known as gauge blocks) are inspection tools that are used in the machining industry. They typically come in an 81-piece set and the sizes in the set are as follows:

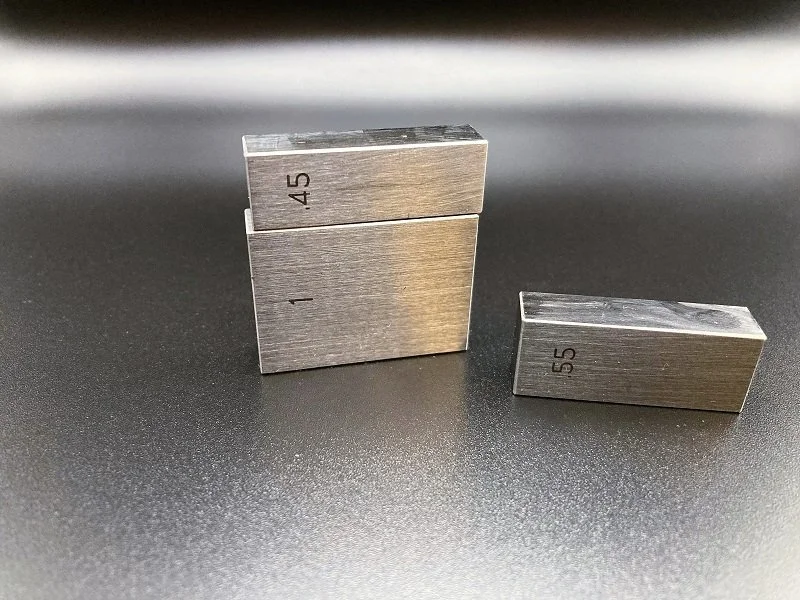

The blocks are joined together to acquire the appropriate height by a process called wringing. When you wring blocks together, you gently slide them and line them up. Since the gage block surface is ultra-flat and smooth, the blocks stay together.

The gage blocks come in different grades. Grade B is made for shop use, and Grade A is for inspection and setting inspection tooling. There is a U.S specification number GGG-G-15C that reclassifies the gages as .5 to 3. Grade 3 is a compromise between the grade A and B.