3D Printed Clock

I have designed and built a 3D printed clock that has over two dozen printed parts in it. My aspirations for doing this started when I bought mechanical watch movements and disassembled them to see how they work. The clock that I printed was inspired by a mechanical watch movement, but it is scaled up in size by six times.

The research, development, engineering, and manufacturing took thousands of hours to complete and was considered a hobby of mine. In my career, I was a journeyman tool and die maker, so I made components and fit and assembled them, so this project to me was very similar to tool and die making.

In the picture below, it is a 3D printed mainspring. It was printed out of PLA material, and it lasted for about thirty uses before it failed. I plan on researching different materials that I could make future springs with and testing them on the clock.

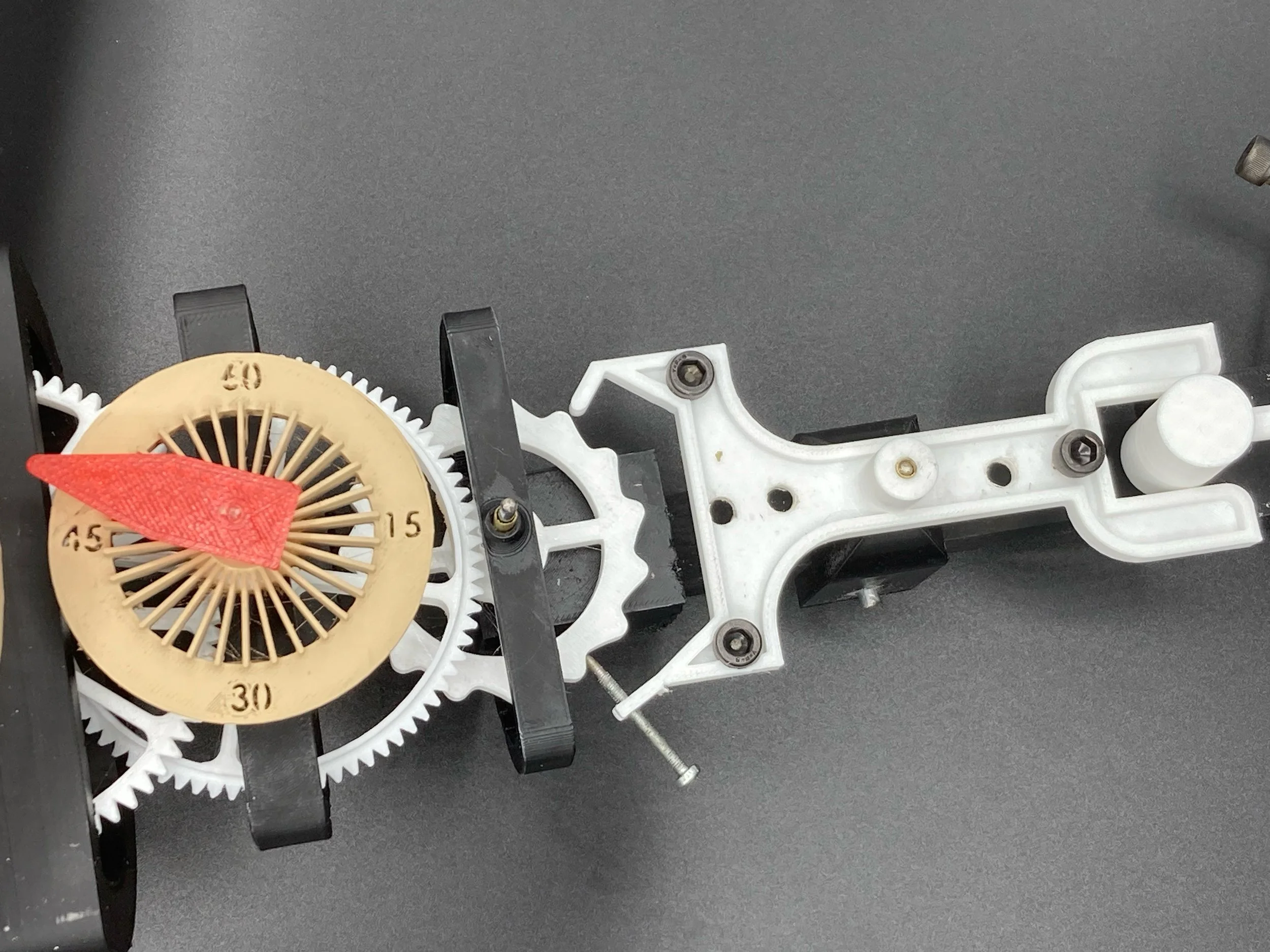

The clock has a few areas that I can adjust the speed of the escape wheel. I have a fine adjustment screw on the fork that is used as a contact point for the escape wheel. The best that I was able to get the clock was it was off 2 seconds in a five-minute study.

The mainspring and clock face

The seconds hand, escape wheel and pallet fork.

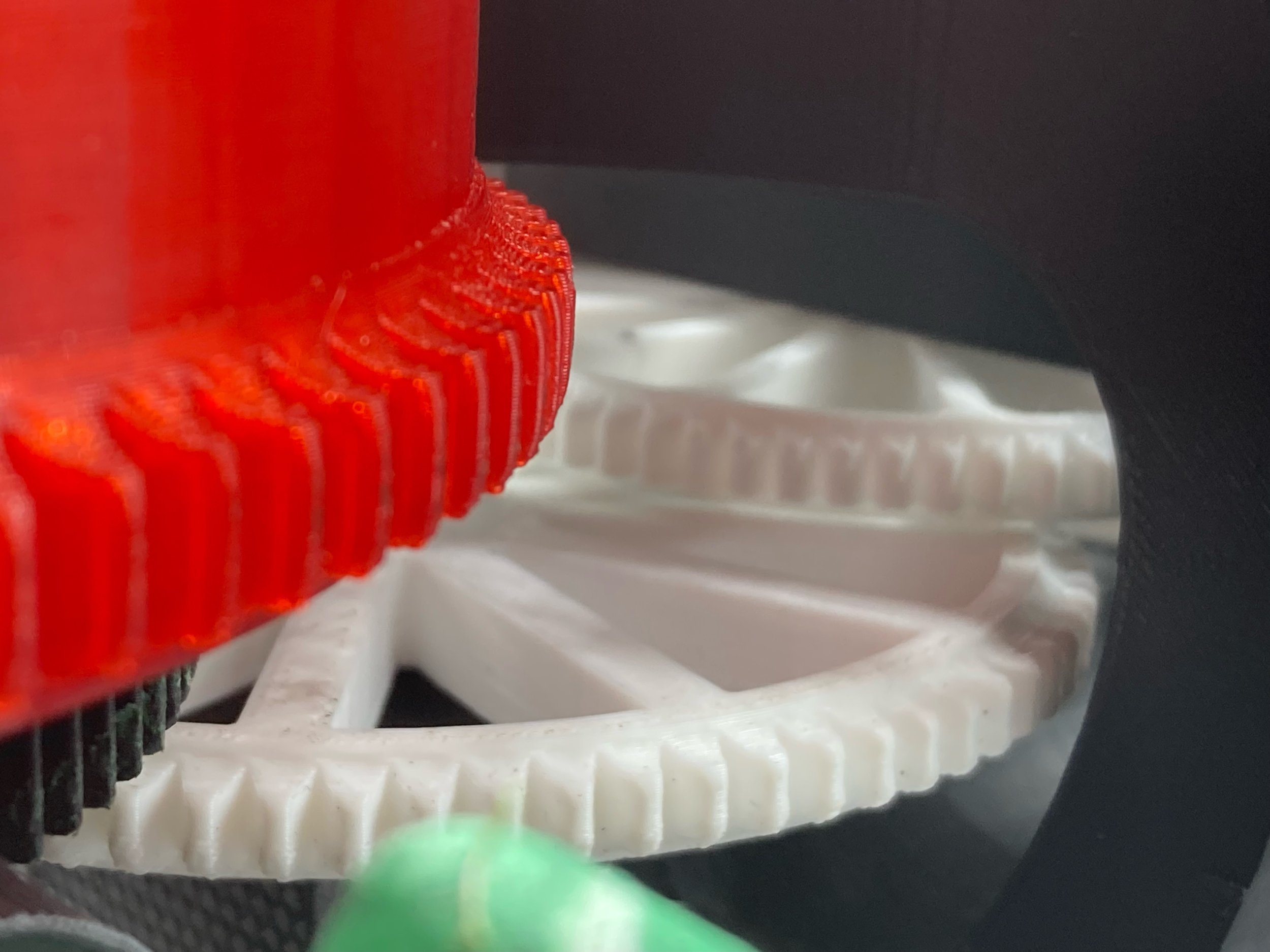

The mainspring barrel gear teeth, and center wheel.

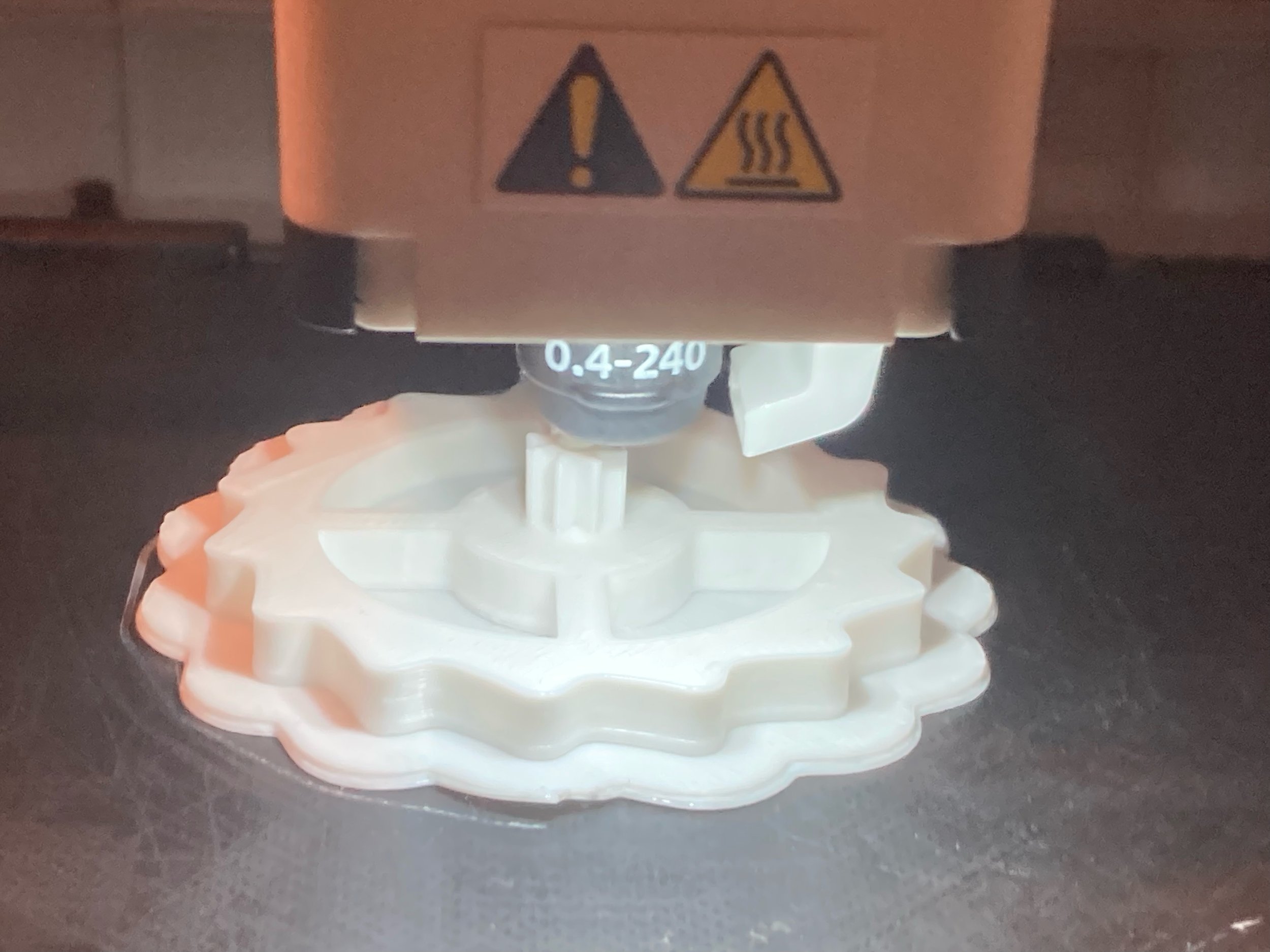

Printing a new escape wheel on a raft.